Spot welding systems automate metal fusion processes in collision repair, offering speed, precision, and consistency for strong bonds. Ideal for complex vehicle panel restoration, these systems face challenges of limited applicability and high cost but are crucial for advanced repairs like bumper restoration and Mercedes-Benz fixes. Future trends include AI optimization and smart sensors to enhance joint strength and aesthetics, streamlining bumper repair for better affordability while maintaining industry standards.

“Uncover the intricacies of spot welding systems, a pivotal technology in collision repairs. This comprehensive guide delves into the fundamental understanding of these systems, exploring their unique advantages and disadvantages for automotive restoration. From enhancing structural integrity to presenting challenges, we dissect the current landscape. Furthermore, discover the latest trends and best practices shaping the future of spot welding technology, offering insights that professionals and enthusiasts alike will find invaluable.”

- Understanding Spot Welding Systems: The Basics Unveiled

- Advantages and Disadvantages: Weighing the Options for Collision Repairs

- Best Practices and Future Trends in Spot Welding Technology

Understanding Spot Welding Systems: The Basics Unveiled

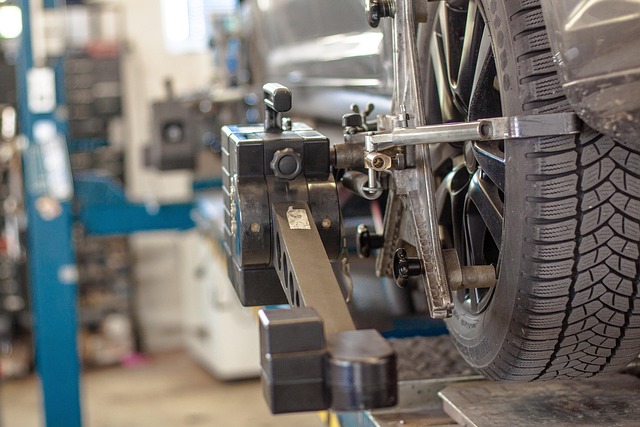

Spot welding systems are a fundamental aspect of modern collision repair processes. These systems use precision technology to fuse metal components together, providing robust bonds that match or even exceed the strength of the original vehicle structure. At their core, spot welding involves applying concentrated heat through specialized tools to melt and intermix the metal surfaces, creating a permanent joint.

This technique is particularly valued in auto body shops and collision repair services for its speed, efficiency, and consistency. Unlike traditional welding methods that require more time and skill, spot welding systems automate the process, ensuring precise results. This not only streamlines vehicle dent repair but also enhances the overall quality of the restoration, making it a go-to solution for professionals in the industry.

Advantages and Disadvantages: Weighing the Options for Collision Repairs

Spot welding systems have emerged as a game-changer in the collision repair industry, offering both advantages and disadvantages when compared to traditional methods. One of the key benefits is their precision and speed. These systems use concentrated heat to join metal parts with minimal distortion, ensuring a strong and accurate bond. This precision is particularly valuable when restoring complex vehicle panels, maintaining the original factory finish and structural integrity.

However, there are challenges to consider. Spot welding may not be suitable for all types of metal or repair scenarios, especially in cases where extensive body work is required. The cost of acquiring and maintaining these systems can also be a significant factor, as they demand specialized training and equipment. For many auto repair near me shops, particularly those offering vehicle repair services and tire services, the decision to invest in spot welding technology depends on their workload and long-term goals, balancing the advantages against potential drawbacks to provide the best possible repairs for their customers.

Best Practices and Future Trends in Spot Welding Technology

In the realm of automotive collision repair, spot welding systems have evolved to become a game-changer, particularly in challenging repairs like bumper restoration and Mercedes-Benz collision repair. As technology advances, best practices continue to refine this process, ensuring precision and efficiency. Automated and robotic systems now offer highly accurate welds, reducing human error and improving productivity, especially in intricate designs. These innovations enable technicians to restore vehicles to their pre-accident condition with minimal impact on quality.

Looking ahead, future trends suggest further integration of AI and advanced materials. Artificial intelligence can optimize welding parameters for different metal types, enhancing joint strength and aesthetics. Additionally, innovative spot welding systems might employ smart sensors to detect and adapt to material variations, ensuring consistent results. Such developments promise to streamline the bumper repair process, making it more accessible and cost-effective while maintaining the high standards demanded in the automotive industry.

Spot welding systems have become indispensable tools in the collision repair industry, offering precise and efficient joining of automotive components. By understanding their advantages, disadvantages, and best practices, professionals can leverage this technology for superior repair outcomes. As spot welding continues to evolve with future trends like advanced automation and innovative material compatibility, it remains a key player in ensuring structural integrity and vehicle performance.