Spot welding systems revolutionize autobody repairs by speeding up processes, minimizing metal damage through precise heat targeting, and ensuring consistent high-quality bonding. These advanced machines cut turnaround times, boost customer service, and reduce costs in collision repair shops, offering Mercedes Benz body shops and others unparalleled efficiency and quality control.

In modern collision repair, efficient and precise joint formation is paramount. Spot welding systems have emerged as a game-changer, offering significant advantages over traditional methods. These advanced systems streamline repairs by enabling fast and strong welds, ensuring structural integrity in vehicle panels. With enhanced precision, cost savings, and reduced downtime, spot welding technologies are essential for collision repair shops looking to optimize operations and deliver high-quality results.

- Efficient Joint Formation: How Spot Welding Systems Speed Up Repairs

- Enhanced Precision: Ensuring Structural Integrity with Modern Technology

- Cost-Effectiveness and Time Savings: Benefits for Collision Repair Shops

Efficient Joint Formation: How Spot Welding Systems Speed Up Repairs

Spot welding systems have revolutionized autobody repairs, significantly speeding up processes that were once time-consuming in car collision repair. These advanced systems use precise, targeted heat to create strong bonds between metal panels, enabling efficient joint formation. By focusing the heat on specific points, spot welding reduces the overall heating of the surrounding metal, minimizing damage and warping, common issues with traditional welding methods.

This efficiency translates into quicker turnaround times for automotive repair shops, allowing them to serve more customers and reduce costs. Moreover, the precision offered by spot welding systems ensures consistent, high-quality results in every joint formed, crucial for maintaining structural integrity in modern vehicles. This level of accuracy is particularly beneficial in complex car collision repair scenarios, where precise alignment and bonding are vital to restore the vehicle’s safety and aesthetic appeal.

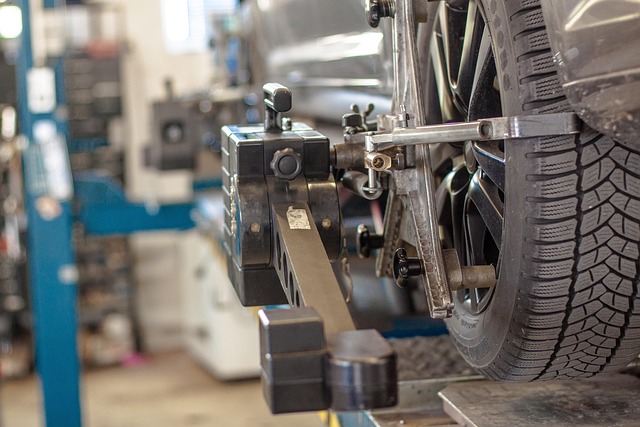

Enhanced Precision: Ensuring Structural Integrity with Modern Technology

In today’s advanced automotive landscape, precision is paramount in car collision repair and body shop services. Modern spot welding systems have revolutionized auto repair shops by offering unprecedented control and accuracy. These systems employ cutting-edge technology to ensure each weld is consistent and exact, maintaining structural integrity throughout the repair process.

With their advanced features, spot welding machines enable technicians to make precise adjustments, resulting in stronger bonds and reduced distortion. This level of precision not only expedites the repair time but also enhances the overall quality of the body shop services, ensuring customer satisfaction and vehicle safety on the road.

Cost-Effectiveness and Time Savings: Benefits for Collision Repair Shops

In today’s competitive automotive industry, efficiency is key for collision repair shops to stay profitable and meet customer expectations. Spot welding systems offer a range of benefits that significantly contribute to cost-effectiveness and time savings. These advanced machines streamline the panel joining process, enabling faster assembly times without compromising on quality. With precise control over weld parameters, automotive body shops can reduce material waste and labor costs associated with traditional welding methods.

For Mercedes Benz repair or any high-quality vehicle body shop, investing in spot welding systems can lead to substantial improvements in productivity. By automating the welding process, these systems ensure consistent, repeatable results, minimizing errors that can arise from manual labor. This not only speeds up repairs but also enhances overall workshop performance, allowing for more vehicles to be serviced within a given timeframe.

Spot welding systems have become indispensable in modern collision repair, offering a range of benefits that streamline processes, enhance structural integrity, and reduce costs. By efficiently forming strong joints, these systems significantly speed up repair times while maintaining precision. This technology is a game-changer for collision repair shops, allowing them to deliver high-quality, cost-effective services with greater efficiency. Adopting spot welding systems is not just a trend; it’s a strategic move towards a more robust and profitable future in the automotive repair industry.