Spot welding systems have revolutionized collision repairs, offering significant advantages in efficiency and quality. These advanced tools apply precise heat to fuse metal, ensuring accurate alignment and connection of damaged auto parts, particularly for frame repairs. The versatility of spot welding enables both structural repairs and cosmetic enhancements, streamlining dent removal and mitigating imperfections. By enhancing vehicle safety and aesthetic appeal, these systems are a key innovation in modern automotive workshops, reducing labor costs and turnaround times while maintaining consistent weld quality.

Spot welding systems have transformed collision repairs, offering precision and efficiency. This article delves into the innovative world of these systems, highlighting their pivotal role in modern automotive workshops. We’ll explore how spot welding enhances structural integrity, reduces repair time, and minimizes material waste. Understanding its key benefits and best practices will equip professionals to maximize the potential of this game-changing technology, revolutionizing the way we approach car repairs.

- Understanding Spot Welding Systems and Their Role in Collision Repairs

- Key Benefits of Implementing Spot Welding Systems

- Best Practices for Utilizing Spot Welding Systems Effectively

Understanding Spot Welding Systems and Their Role in Collision Repairs

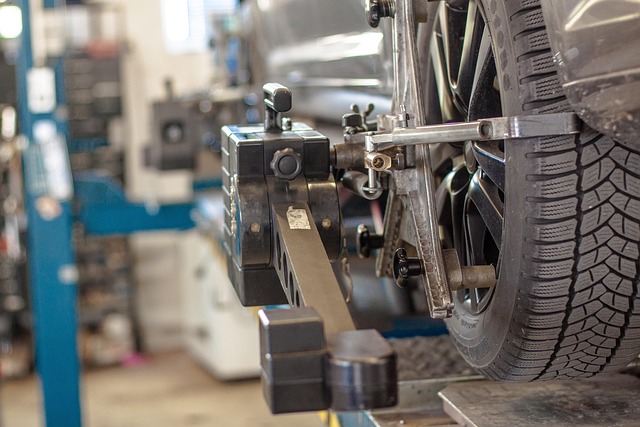

Spot welding systems have become indispensable tools in the realm of collision repairs, offering a range of benefits that enhance efficiency and quality. These advanced systems utilize concentrated heat to fuse metal, creating robust bonds in a matter of seconds. This precise and controlled process is particularly valuable for auto frame repair, where aligning and connecting damaged vehicle components accurately is paramount.

By employing spot welding, professionals in auto body restoration can streamline the dent removal process and minimize the risk of structural weaknesses or visible imperfections. The versatility of these systems allows for both structural repairs and cosmetic enhancements, making them a game-changer in modern automotive workshops. This technology ensures that vehicles not only return to their pre-accident condition but do so with enhanced safety and aesthetic appeal.

Key Benefits of Implementing Spot Welding Systems

Implementing spot welding systems offers numerous advantages for collision repairs, revolutionizing car bodywork services and significantly enhancing efficiency in auto maintenance workshops. These systems enable precise and robust welds, ensuring structural integrity and a seamless finish on vehicle panels. This precision is particularly beneficial when addressing minor dents or damage, such as car scratches, allowing for more effective and cost-efficient repairs compared to traditional methods.

The use of spot welding systems streamlines the repair process, reducing the time required for complex repairs. This efficiency translates into lower labor costs and faster turnaround times, making it a game-changer in the industry. Moreover, these systems promote consistency and repeatability, ensuring that each weld is of the highest quality, which is vital for maintaining the structural integrity and overall safety of vehicles undergoing collision repairs.

Best Practices for Utilizing Spot Welding Systems Effectively

To leverage spot welding systems effectively in automotive collision repair, best practices include ensuring proper training for technicians on the latest equipment and techniques. This involves regular workshops and certifications to keep up with advancements in spot welding technology. Utilizing the right tools and maintaining them in excellent condition is paramount; dirty or damaged guns can lead to poor welds.

Furthermore, preparation is key. Before initiating spot welding, meticulous metal preparation, including cleaning and degreasing, is essential. Aligning components precisely and using suitable weld settings based on material types and thicknesses guarantees high-quality frame straightening results. Incorporating these practices into standard auto repair services enhances efficiency, reduces rework, and ensures customers receive top-notch automotive collision repair services.

Spot welding systems offer a multitude of benefits for collision repairs, from increased efficiency and reduced material waste to improved structural integrity and faster turnaround times. By implementing these advanced systems, automotive repair shops can elevate their standards, reduce costs, and better serve their customers. Adhering to best practices ensures the optimal use of spot welding technology, making it a game-changer in modern collision repair processes.