Spot welding systems, advanced machines using focused energy beams like lasers or resistance to melt and fuse metal pieces, are crucial in various industries, particularly automotive repairs, for their precision and efficiency. In Mercedes-Benz repair, these systems maintain original manufacturing quality by allowing accurate localized melting of damaged panels without impacting surrounding areas. They streamline collision repair processes while preserving structural integrity and aesthetics, making them indispensable in modern workshops. However, spot welding systems have limitations, such as being suitable primarily for lighter gauge metals, which should be considered when integrating them into automotive repair services.

Spot welding systems play a pivotal role in modern vehicle repairs, offering precise and efficient joining of metal components. This article delves into the world of spot welding, exploring its fundamentals, advantages, and applications within the automotive industry. From enhancing repair speed to ensuring structural integrity, spot welding systems are indispensable tools for professionals. We’ll also analyze their limitations, providing a comprehensive understanding of this game-changing technology in automotive restoration.

- What are Spot Welding Systems?

- How Do Spot Welding Systems Facilitate Vehicle Repairs?

- The Benefits and Limitations of Using Spot Welding Systems in Automotive Industry

What are Spot Welding Systems?

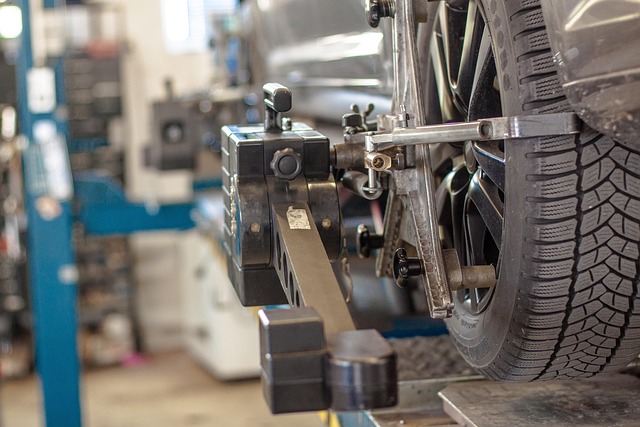

Spot welding systems are advanced machines designed for precise and efficient metal joining, playing a pivotal role in various industries, including automotive repairs. These systems utilize concentrated energy beams, typically laser or resistance, to melt and fuse two or more metal pieces together, creating strong and permanent bonds. This process is highly sought after in vehicle restoration and fender repair due to its ability to ensure structural integrity while minimizing material waste.

In Mercedes-Benz repair, for instance, spot welding is instrumental in restoring the precision and quality of original manufacturing. By allowing for accurate, localized melting, these systems can fix damaged panels without affecting surrounding areas, leading to superior results in body shop operations.

How Do Spot Welding Systems Facilitate Vehicle Repairs?

Spot welding systems play a pivotal role in modern vehicle repairs, revolutionizing the way car body restoration and collision repairs are conducted. These advanced systems enable precise and efficient joining of metal components, which is essential for mercedes benz repair and other high-quality automotive work. By using focused heat to fuse two metal surfaces together, spot welding offers a strong, durable bond—a key advantage over traditional welding methods.

In a collision repair shop, spot welding systems streamline the process by allowing technicians to quickly and accurately mend damaged panels, ensuring structural integrity without compromising aesthetics. This precision is particularly crucial for intricate car body restoration projects, where every detail matters. The versatility of spot welding systems further enhances their value, making them indispensable tools in modern automotive workshops.

The Benefits and Limitations of Using Spot Welding Systems in Automotive Industry

Spot welding systems have become indispensable tools in the automotive industry for good reasons. One of their key benefits is precision and speed; these systems allow for quick and accurate welds, reducing repair times significantly. This efficiency is particularly valuable in high-volume production lines where minimizing downtime is crucial for maintaining profitability. Moreover, spot welding offers consistent quality, ensuring that each repair is carried out to the same high standard, which is essential for safety and customer satisfaction.

However, despite these advantages, spot welding systems also come with certain limitations. They are primarily designed for joining lighter gauge metals, making them less suitable for heavier car body parts that require stronger bonds. In complex auto maintenance scenarios involving intricate car bodywork, spot welding might not be the go-to solution due to its relatively simple design and functionality. As such, understanding these strengths and weaknesses is vital when considering the role of spot welding systems in modern automotive repair services and auto maintenance routines.

Spot welding systems play a pivotal role in modern vehicle repairs, offering precise and efficient joining of metal components. By facilitating faster, stronger, and more cost-effective assembly, these systems are integral to the automotive industry’s continued evolution. While they present certain limitations, such as material compatibility issues and specialized training requirements, ongoing advancements promise to further enhance their effectiveness, solidifying their position as a indispensable tool in the repair landscape.